UV Vacuum Metalising Plant

- Home

- UV Vacuum Metalising Plant

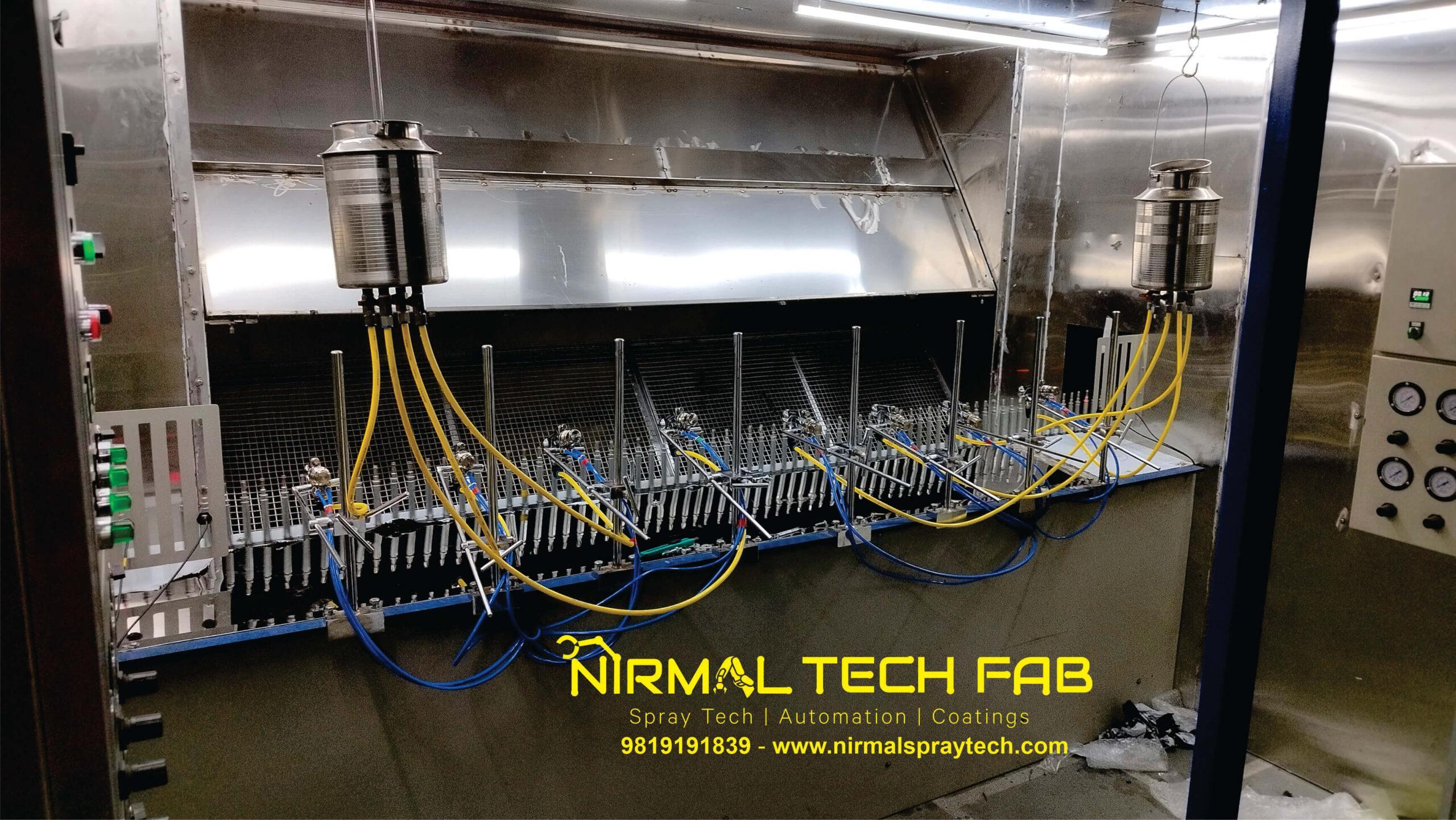

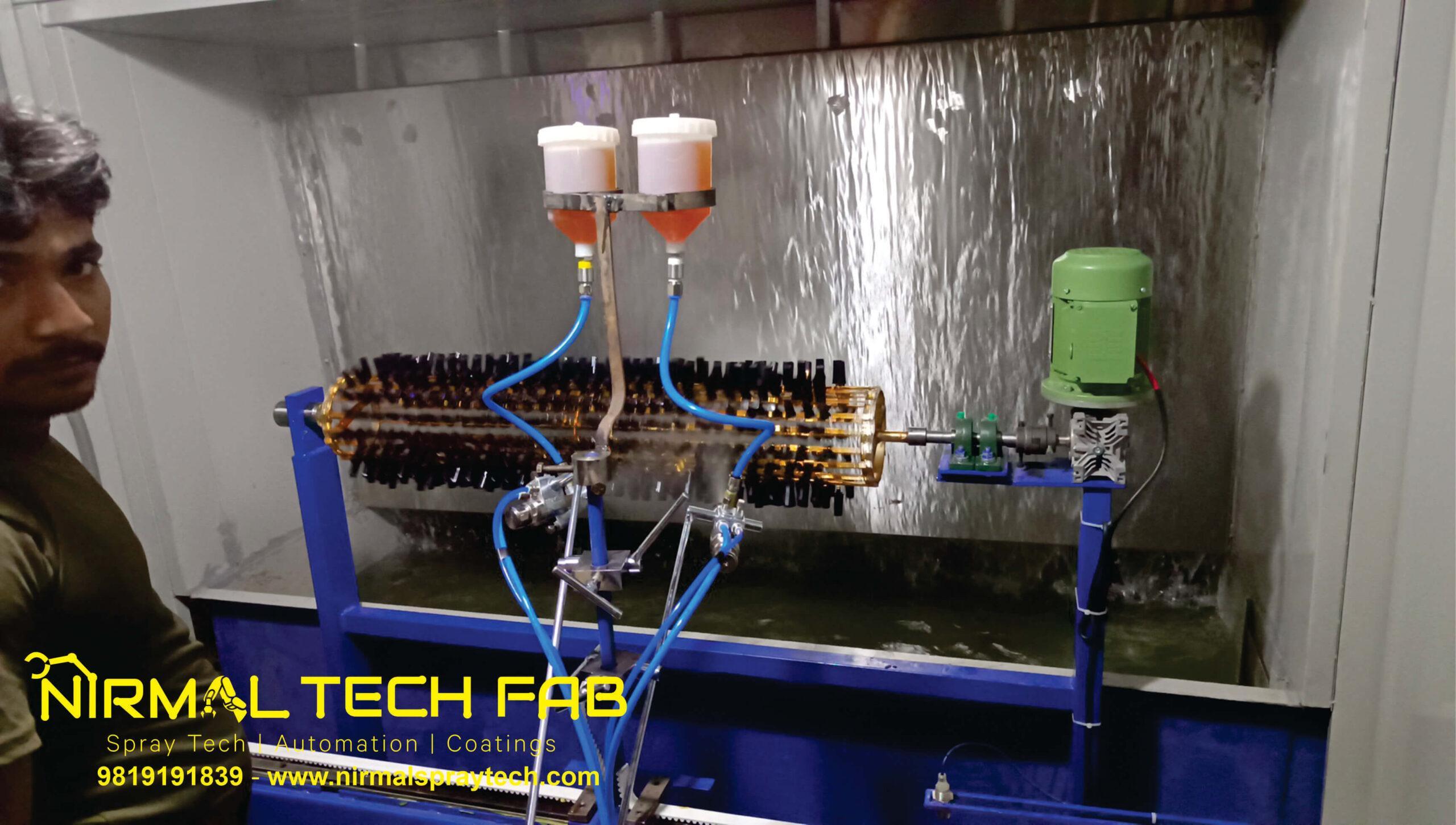

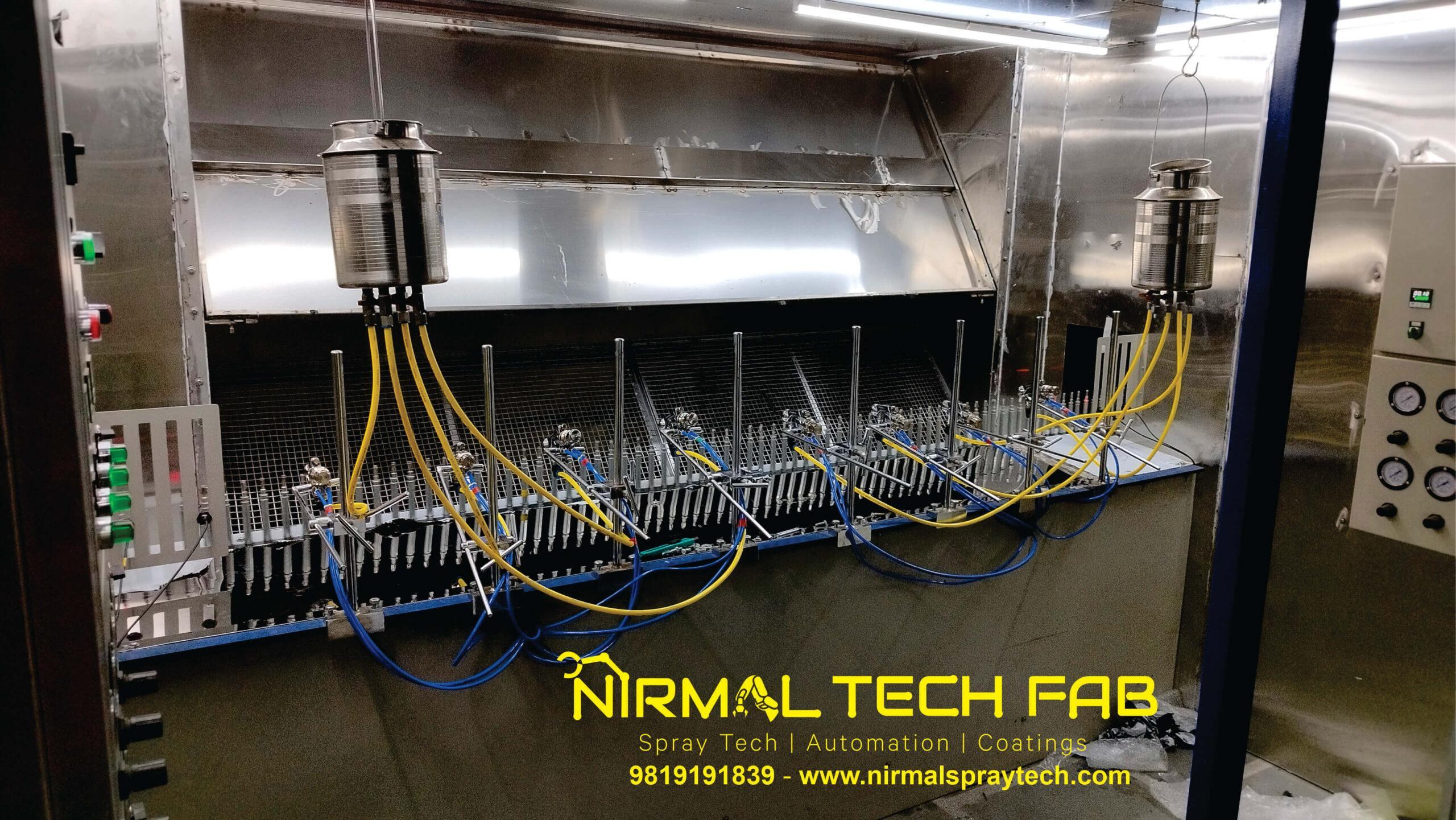

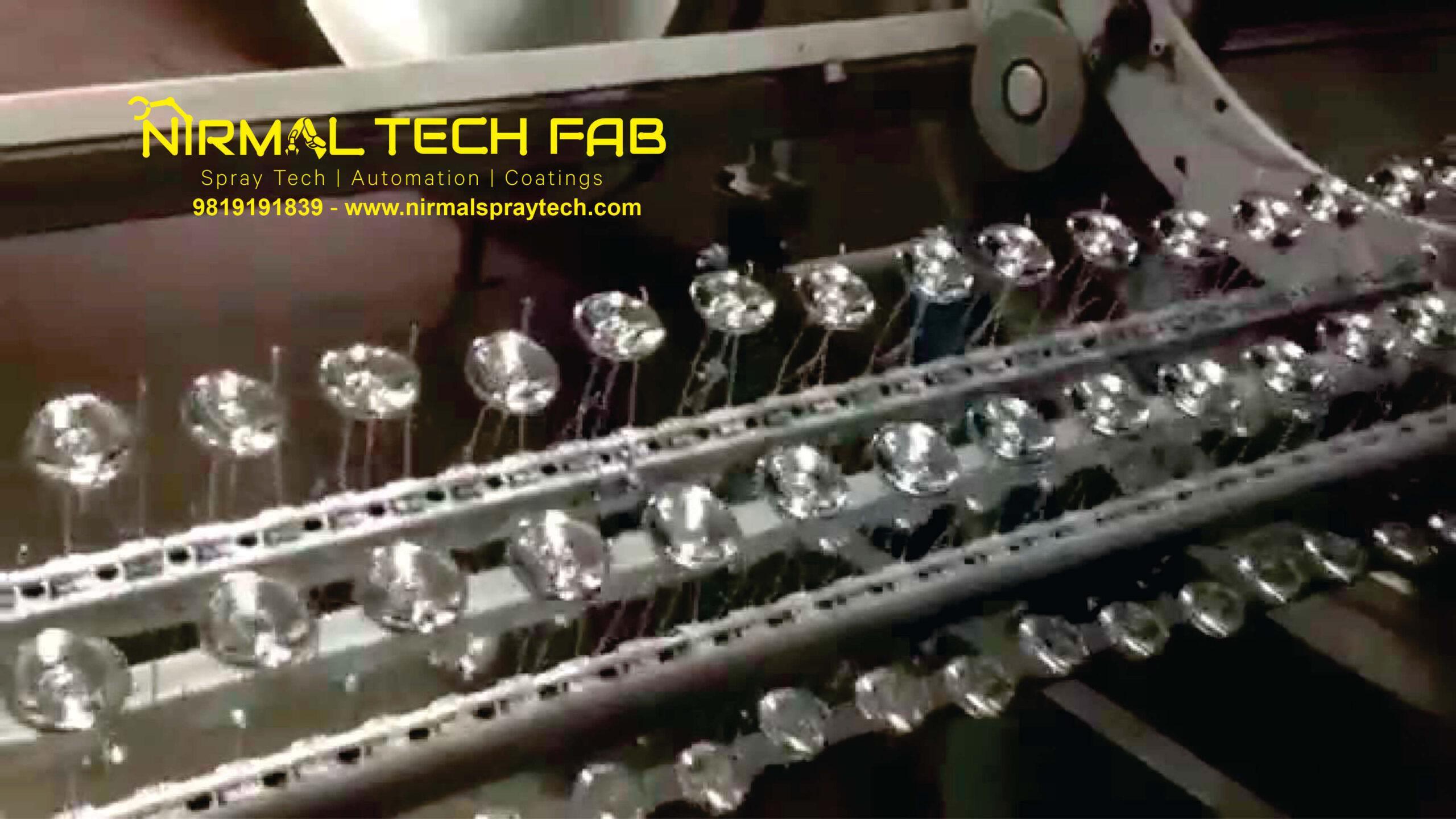

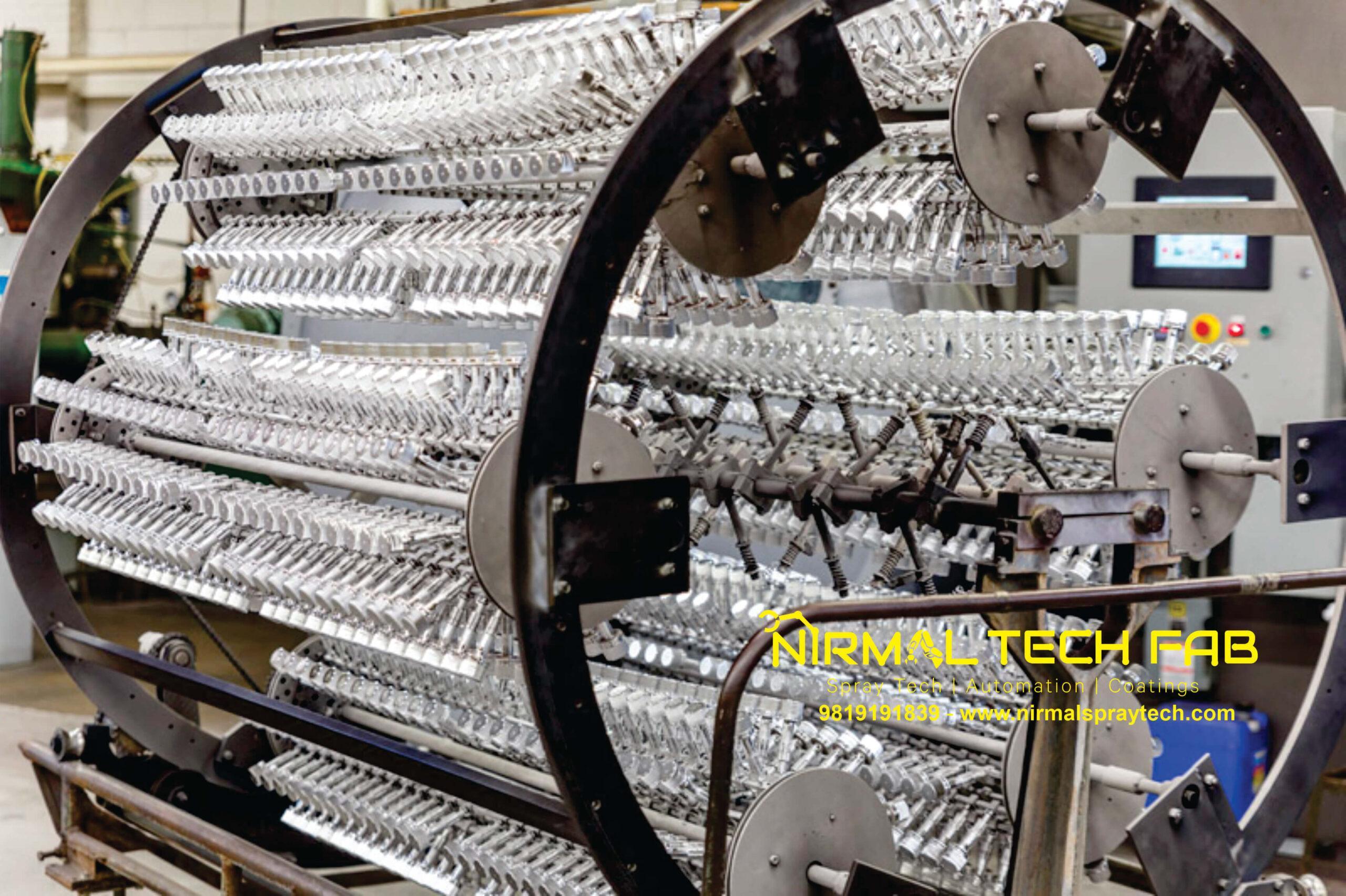

UV Vacuum Metalising Plant

A UV vacuum metalizing plant is a high-tech manufacturing system that applies a thin layer of metallic coating to various types of substrates using a vacuum deposition process. This process involves heating a metal in a vacuum chamber until it evaporates and then condenses onto the surface of the substrate, creating a thin, uniform coating that provides the desired aesthetic and functional properties.

Nirmal Tech Fab is a leading manufacturer of UV vacuum metalizing plants that are designed to meet the highest standards of quality, efficiency, and reliability. Their plants are equipped with state-of-the-art technology and advanced features that ensure precise and consistent metalization results.

Some of the key features of a UV vacuum metalizing plant from Nirmal Tech Fab include:

1. High-speed metalization: These plants are designed to achieve high-speed metalization of a wide range of substrates, including plastics, glass, metals, and ceramics.

2. Efficient material usage: The vacuum deposition process used in these plants ensures that the metallic coating is applied precisely and efficiently, minimizing waste and reducing costs.

3. Uniform coating: The advanced technology used in these plants ensures that the metallic coating is applied evenly and uniformly, resulting in a high-quality finish.

4. Customizable designs: Nirmal Tech Fab offers a range of customizable designs to meet the specific needs and requirements of their clients.

5. User-friendly interface: The plants are designed with a user-friendly interface that allows operators to easily control and monitor the metalization process.

Overall, a UV vacuum metalizing plant from Nirmal Tech Fab is a high-tech and reliable manufacturing system that provides precise and efficient metalization of a wide range of substrates.